Tipi personalizzati di stampaggio a iniezione di plastica per connettori elettronici e ricambi auto

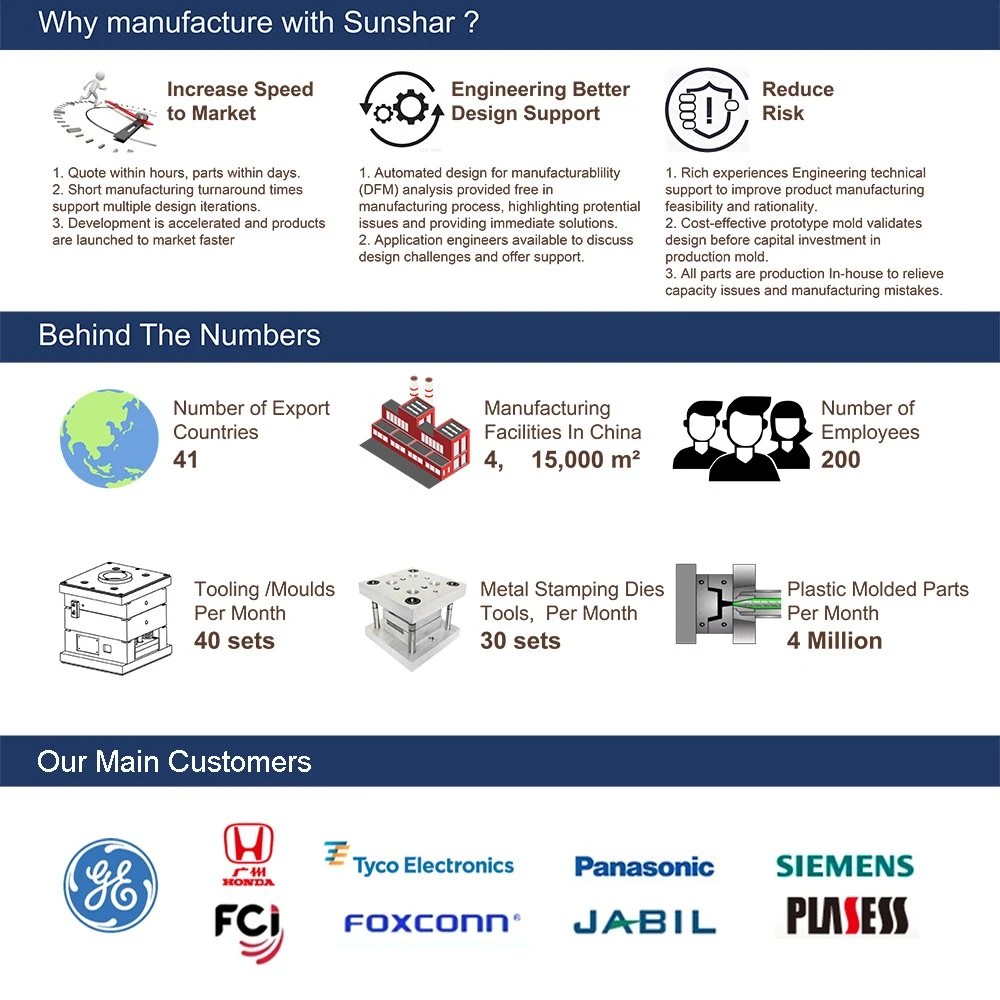

Perché scegliere Sunshar? Sunshar offre un servizio completo per lo stampaggio a iniezione di materie plastiche e di gr

Descrizione

Informazioni di base

| Modello numero: | Stampaggio a iniezione |

| Tipo di plastica | Plastica termoindurente |

| Stampo di plastica | cereali |

| Processo di stampaggio | Stampaggio a iniezione |

| Materiale | PA66+30GF |

| cavità | Multi-cavità |

| Venditore caldo | Judo |

| Stahl | 1.2344 |

| macchina per iniezione | 60-600 tonnellate |

| Applicazione | Industria elettronica, automobilistica, elettrodomestici |

| Tempo di riciclaggio | Anni 6-60 |

| ore lavorative | 2 turni 24 ore |

| Atti | Automaticamente |

| tempi di consegna | 3-15 riprese |

| Quantità di ordine minimo | Piccolo ordine accettabile |

| Regolare | OEM/ODM |

| Pacchetto di trasporto | Kartonverpackung |

| specifica | 80x50x30 |

| marchio | OEM/ODM accettabile |

| Origine | Cina |

| Codice HS | 3926909090 |

| Capacità produttiva | 100 |

Descrizione del prodotto

| SUNSHAR PRECISION TECHNOLOGY CO., LTD | |

| AGGIUNGI: distretto di Shangjiao, città di Chan'an, città di Dongguan, provincia del Guangdong, Cina. 523878, | |

| Contattaci: https://spt-injectionmolding.en.made-in-china.com/contact-info.html | |

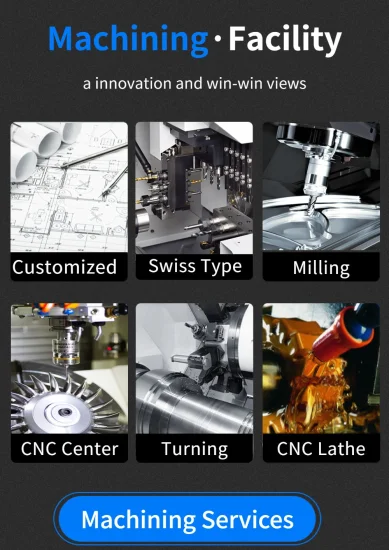

| Specifiche degli strumenti di stampaggio Sunshar: | |

| Standard di stampo: | AISI, DIN, JIS |

| Norma base dello stampo: | HASCO, DME, LKM, FUTABA |

| Forma acciaio: | H13, 1040, 420, P20, 0-1, S-7, D2, A2, 1.2343, 1.2344, 1.2083, 1.2311, 1.2379, 1.2510, 1.2767, 1.1730, P5, NAK55, NAK80, SKD61, SKD 5 1 , S136, S136H, 8407, M333, 718H |

| PC, PC+ABS, ABS, PBT, LCP, PBT+GF, POM, Nylon, PEEK, PE, HDPE, PP, AS, PS, PP+PULVISTALCI, PET, TPU, PPS, PSU, PPO | |

| Classificazioni della forma SPI: | 101,102,103,104, 105 |

| Stile modulo: | Stile dello stampo: stampo a 2 piastre, stampo a 3 piastre, stampo multipiastra, MUD, stampo a 2 componenti |

| Corridore: | Cancello Sprue, Cancello Edge, Cancello Pin Piont, Cancello Banana, Cancello sottomarino, Cancello ad anello, Cancello Slim/Flash |

| Sistema di raffreddamento: | acqua fredda, riscaldamento a gasolio |

| Sistema a canale caldo: | MOLD-MASTERS, INCOE, HUSKY, SYNVENTIVE, YUDO, EVIKON ecc. |

| Finitura superficiale: SPI (DME) | Polacco: A0, A1, A3, B1, B2, B3, C1, C2, C3, D1, D2, |

| VDI 3400-Standard: (HASCO) | Elettroerosione: 0,3,6,9,12,15,18,21,24,27,30,33,36,39,42,45 |

| Pacchetto: | PLY legno, cartone, sacchetti in PP ecc. |

| Voci di pagamento: | Acconto 40%, materiale ordinato 40%, campioni T1 20%. |

| Tempi di consegna: | 15-35 Ripresa (normale) |

| Metodi di spedizione: | Tramite DHL, Fedex, UPS, TNT ecc. O via mare da Shenzhen |

A: By express (FedEx, UPS, DHL, TNT, EMS, etc...), By Air or by sea. Q. How do I pay for the order? A. The common payments are T/T (Telegraphic Transfer), western union, PayPal is also available. Q. I have an idea for a new product, but don't know if it can be manufactured. Can you help?A. Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs. Q. What are the advantages to having my parts manufactured locally?A. Sunshar can offer quick reaction times to any changes in specification, batch size or material. We can ship small or large quantities anywhere in Europe overnight to accommodate unforeseen changes in demand. Q. My components have already been developed on CAD. Can you use the drawings?A. Yes! DWG, DXF, IGS, SolidWorks, Pro/E, UG and Catita files can all be used to generate quotes, models and mould/tools - this can save time and money in producing your parts. Q. Can I test my idea/component before committing to mould/tool manufacturing?A. Yes, we can have the CAD drawings to make Computer simulation for designing and functional evaluations. Q. What type of plastic is best for my design/component?A. Materials selection depends on the application range and the environment situation in which it will function. We will be happy to discuss the alternatives and suggest the best material. Q. What type of mould/tool do I need?A. Mold/tools can be either single cavity (one part at a time) or multi-cavities (2,4, 8, 16 up to 64 parts at a time). Single cavity tools are generally used for small volume demand, up to 20,000 parts per year. And multi-cavities tools are for larger demands. We will according to your estimated annual volume demand and recommend the best solution for you. Q. Ok, I've decided to go ahead with my project. How long will it take to get my parts?A. It will take 3-8 weeks to have the mould/tool manufactured. It depends on the part's size, construction complexity and the number of cavities (single or multi). After your final approval for the quality new tool, you can expect the parts delivered within 2-3 days.

Il nostro contatto

Spedisci ora